Decarbonisation efforts worldwide, led by industry leaders and legislation, have increased the need to shift fossil fuel use to renewables. One way many industrial organisations can embrace this is by shifting process heater systems from fuel-burning to electric. However, the transition is not as simple as throwing a switch. Here, Dennis Long, chief system designer for the energy and environmental technologies business unit at industrial heating equipment manufacturer Watlow, explains how manufacturers can make the electric switch, and why it should happen sooner rather than later.

The tides are turning when it comes to process heating. Pressures to electrify all industrial processes are increasing and electric heaters can offer an effective, environmentally friendlier solution. One of the biggest developments in electrification for process heating is in reliable medium voltage process heating systems.

Changing attitudes

According to the Environmental Protection Agency (EPA), a substantial portion of global greenhouse gas emissions comes from industrial sources burning fossil fuels. Much of this energy is burned on-site for energy and heating needs. The U.S. Energy Information Administration (EIA) estimates that the industrial sector uses approximately 24 quadrillion British Thermal Units (BTUs) of heat per year — roughly one third of the nation’s delivered energy supply. Process heating applications alone account for 36 percent of total delivered energy consumption within the manufacturing sector.

As a result, the pressures to decarbonise and electrify wherever possible are increasing. The demand is not being urged just by governments, but also from non-profits and business leaders for quite a few years too. For example, in 2018, the Bank of England stated the financial sector has been “too slow in divesting investments into fossil fuels” and warned that assets could become useless. Then, in May 2021, after years of protests, a Dutch court ruled that global energy and petrochemical company, Shell Energy, must reduce its carbon emissions by 45 per cent by 2030.

Following this, companies industry wide are quickening decarbonisation of their operations. In fact, Watlow found in a survey that over 90 per cent of respondents in the gas and oil industry have developed, or are in the process of developing, a long-term strategy to reach sustainable, low carbon site statuses.

The electrification of heat

Electrification of process heating is one of the key strategies for addressing climate change concerns in oil and gas. Electric heaters do not burn fossil fuels and can be powered via renewable energy sources. Electric heat exchangers are no stranger to oil and gas operations, but historically, they have been used only in applications with a name plate under one megawatt (MW).

However, there is growing potential to use electric heaters for applications requiring more than one MW but less than 15 MW. These span several areas, including oil and gas production, but also renewable fuel production, ammonia production and carbon recycling.

Besides reducing the use of fossil fuels, electric heaters and heat exchangers have other advantages including less thermal lag, safer operation, more uniform distribution of heat and smaller overall footprint.

Can electric really pull its weight?

What matters most in achieving process heating parameters is not the method of heating, but the heat flux of the heating surface. When it comes to these kinds of applications, electric heaters can safely achieve operating temperatures comparable to gas-fired heaters and with better uniformity and control.

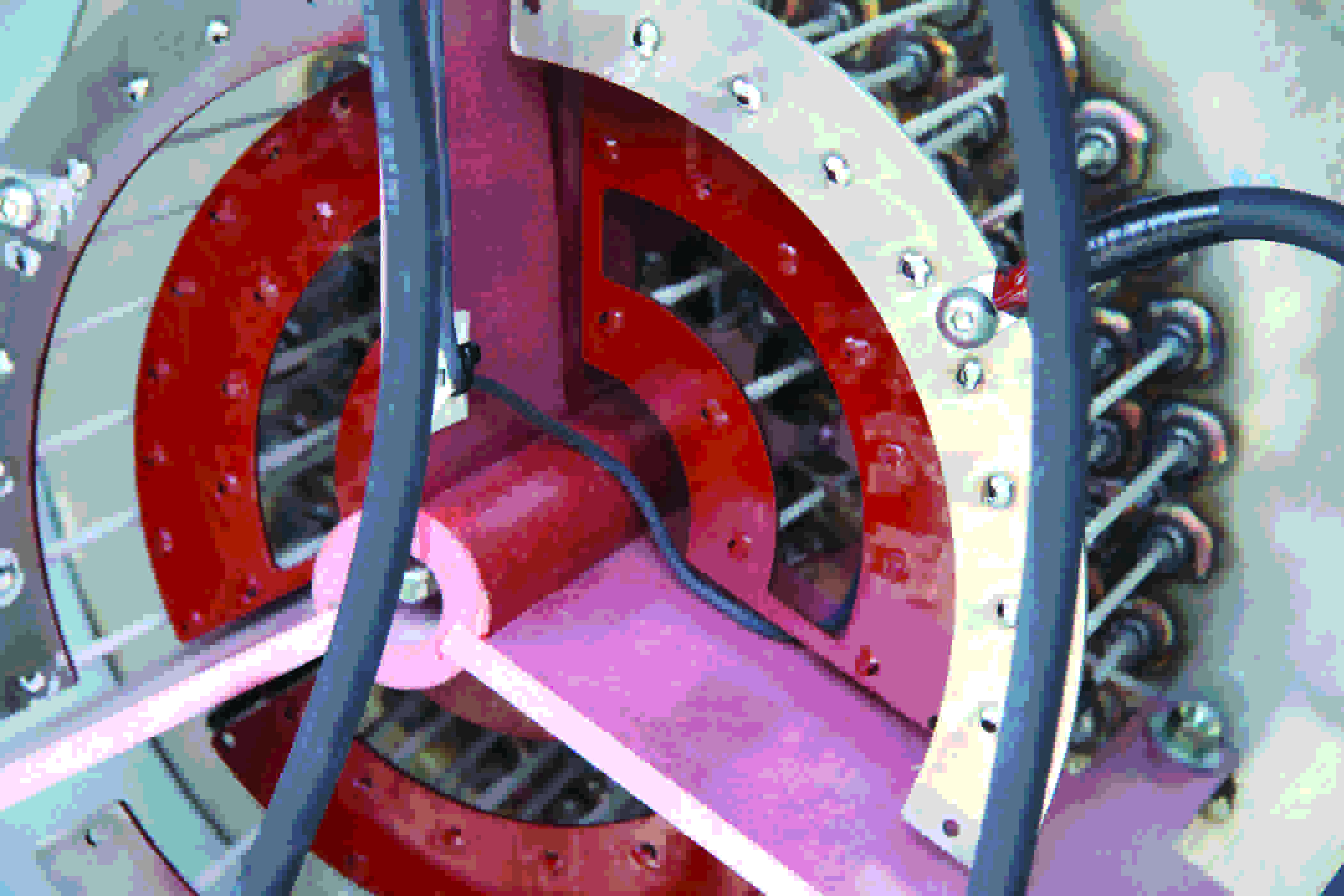

Watlow, which has manufactured industrial electric heaters for almost a century, has recently introduced its POWERSAFE integrated medium voltage control and heating solution — a safe, reliable and clean replacement for fossil fuel alternatives in process equipment.

The POWERSAFE system integrates an electric heat exchanger, process controller and power system, as well as an isolated low voltage enclosure including a human machine interface (HMI) and programable logic controller (PLC). It also incorporates a flexible combination of a silicon-controlled rectifier (SCR) and contactor circuits up to 20 MW, delivering high-efficiency power greater than 99 per cent, which reduces the overall size and weight of the solution.

Furthermore, wattage size requirements for electric thermal equipment are increasing, which makes medium voltage solutions attractive because they reduce overall installation costs of unnecessary cables and transformers. It also offers additional safety benefits such as a high-speed protective relay and breaker for rapid shut down to protect personnel and equipment and safety interlocks for protection during operation.

Watlow is contributing to the decarbonisation needs of many industries that, historically, have had the greatest challenges in controlling emissions. A medium voltage solution such as POWERSAFE helps to make the transition from fuel to electric as seamless as possible.