Recent research has revealed ten unexpectedly explosive materials, including everyday items like sugar and flour, due to combustible dust.

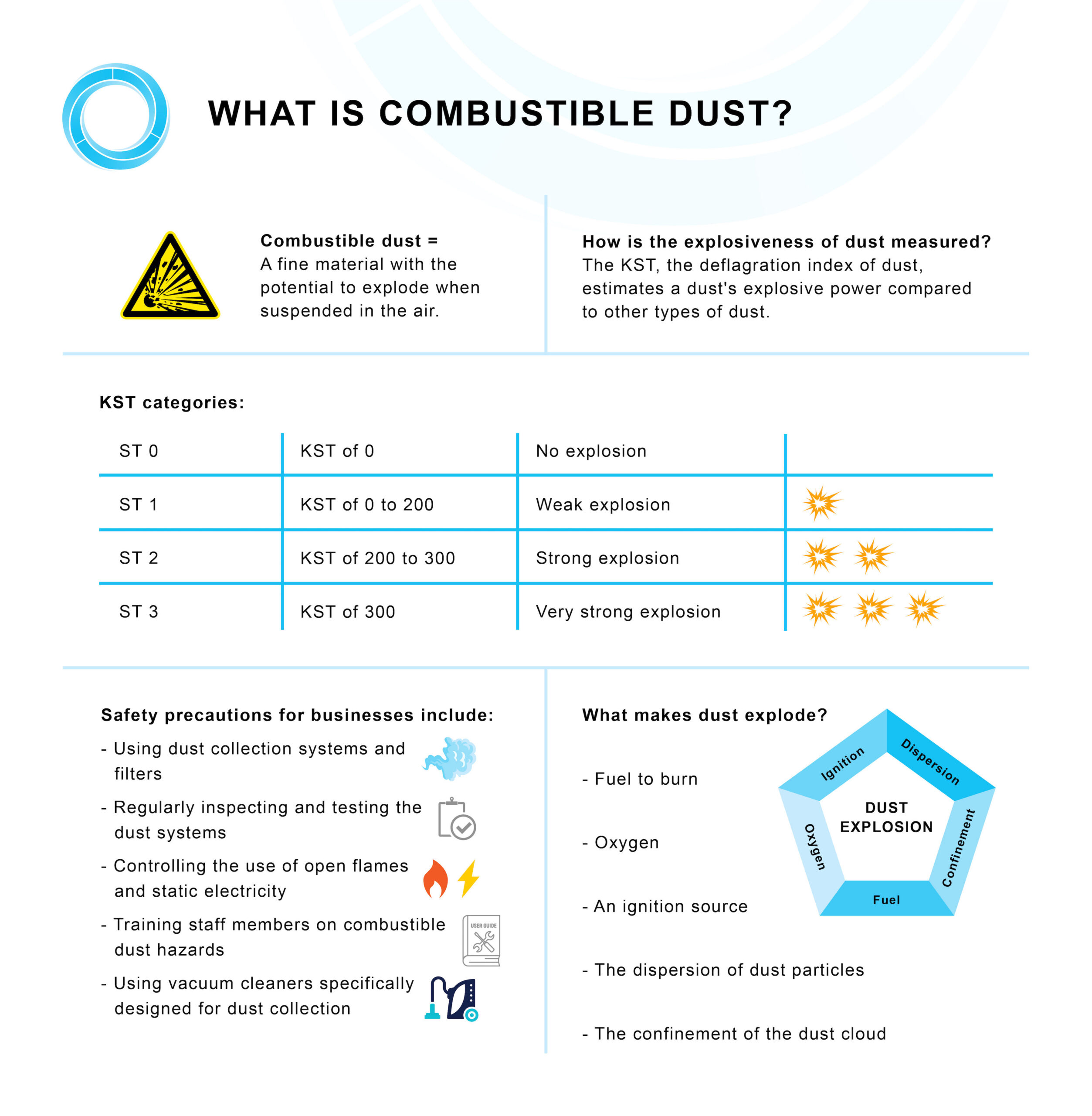

Experts in dust extraction, Extraction Solutions, found the explosive power of ten non-suspecting materials using the KST deflagration index of dust, which ranges from no risk of explosion (ST 0) to a very strong explosion rating (ST 3).

Of the materials included in the research, sugar and orange instant drink had the highest explosiveness rating of ST 2, which signifies the potential for a strong explosion.

Powdered sugar consists of carbohydrates which makes it susceptible to igniting when becoming too hot. The highly flammable chemical limonene naturally occurs in oranges.

David Night, Spokesperson for Extraction Solutions, said: “Underestimating the danger of combustible dust can lead to disastrous fires that put the safety of staff members at risk.

“Even though most of these materials containing combustible dust have a weak explosive rating, recent incidents have shown that they can still cause severe damage and should be taken seriously.”

Combustible dust is classed as any fine material with the potential to explode when suspended in the air.

Three elements are needed to spark a fire, known as the ‘fire triangle’, consisting of fuel to burn, oxygen, and an ignition source. However, two additional factors are needed to cause a dust explosion, forming the ‘dust pentagon’.

These elements entail the dispersion of dust particles in the right concentration and the enclosure of the dust cloud, which enables a build-up of pressure.

David Night added: “Avoid activities that push a lot of particles into the air, like kneading dough or mixing powdered ingredients next to an ignition source, such as a lit gas hob, candles, or other naked flames.

“If you spill ingredients such as flour or sugar, clean them using a wet mop or cloth, as moisture captures the particles, whereas dry methods for cleaning like brooms kick the particles up into the air.

“A domestic vacuum may seem like an easy option to clean a spillage, but fine particles can clog filters and cause the hoover to push particles back out into your home.”

The findings discovered that flour, which also contains carbohydrates, had an estimated weak explosion power (ST 1), but safety precautions are still required.

David Night added: “Businesses such as warehouses and factories face more risk of an explosion due to the quantities of material and dust involved.”

In February 2021, a fire occurred in a flour mill due to a faulty dust collector system, but luckily, no injuries were reported.

David Night continued: “Another positive to reducing airborne particles in the kitchen is a reduced risk of irritating your respiratory system. Research from last year shows that bakers and flour confectioners are at a higher risk than other professions of developing asthma.”

The research found that some of the ingredients used in a cup of coffee, including coffee beans and milk alternatives, had an ST 1 explosive power.

Dairy-free milk powder contains sodium aluminosilicate, which is an anti-caking agent and can ignite when exposed to an open flame.

In 2018, there was a fire at a Dartford coffee roastery. It was contained in the warehouse but is believed to have destroyed 200 tonnes of coffee.

It reportedly took firefighters an entire day to fully extinguish the coffee, which entailed turning it over and then dampening it.

David Night added: “If an explosion destroys the products or facilities, the business will face a huge drop in productivity due to the time required to rebuild machinery. Fines, settlement payments or jail time could also be a risk, depending on the safety breaches and liability.

“Identifying the risks of the material will help you develop a suitable strategy for removing the hazards.”

Businesses handling or storing combustible dust must assess the KST rating and implement the appropriate safety measures to mitigate the risk of explosions.

David Night concluded: “Training staff members on the combustible dust hazards and forming an ignition control program is crucial to prevent accidents.

“Businesses should also supply equipment that will minimise the explosive risks, including dust collection systems and filters, vacuum cleaners specifically designed for dust collection, and cleaning systems that don’t produce dust clouds.

“Regularly inspect and test these systems, too, and check the suitability of electrical equipment and wiring methods. As well as this, ensure heated systems and surfaces are kept away from combustible dust and control the use of open flames and static electricity.”